Intro

I am experienced at dealing at all levels of business whether its at board room level, engineering level or installation production level. Where I differ from other sales experienced people is I come from a technical background and I’ve maintained an active technical role whilst also looking after sales, account management and commercial negotiations. This has given me a broad experience which is transferable between technical and commercial roles across many different industries and disciplines whether nuclear, power or industrial sectors on control, instrumentation, electrical and mechanical projects.

I am very flexible in providing services either on a full time long term basis right through to a call off contract for services as and when required. Please feel free to get in touch to discuss your specific needs.

Business Development

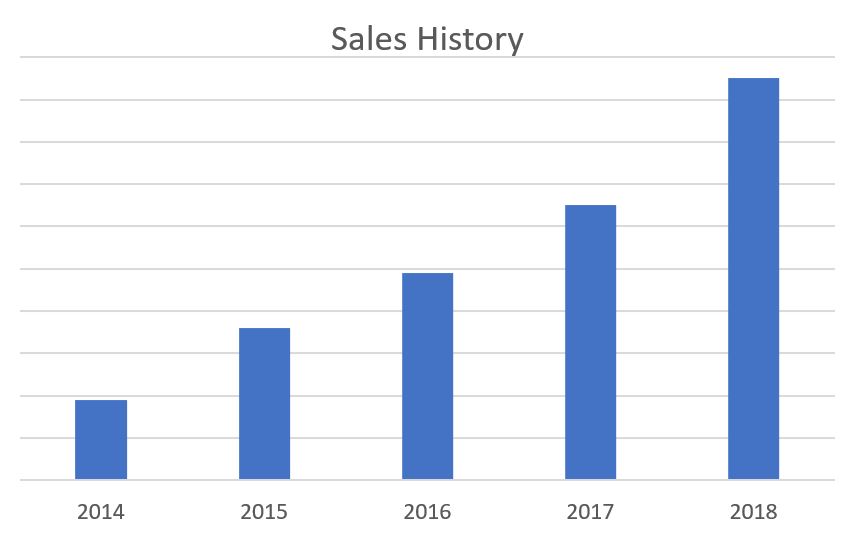

My past sales targets and achievements

2014 Started as a Business Development Manager.

2015 increased sales on 2014 by 89%

2016 increased sales on 2015 by 36%

2017 Increased sales on 2016 by 33%

2018 Increased sales on 2017 by 70%

Achieved year on year growth and the highest performing BDM for my previous employer.

So, what’s my secret?

I am a strong believer in listening to what the customer is saying and really try to help them. Its not about pushy sales techniques it about being a trusted adviser. Striving to be someone you can go to for advice and will give you an honest answer. Its also about being fair and reasonable on both sides of the fence. If you can master listening to your customers needs and getting to understand what is important to them then you start to see their perspective. Also developing an open relationship where you can realign a customer’s expectations if they are unreasonable or are just not deliverable.

Being able to talk technically and develop a solution with your customers without having to stop the conversation and rearrange a meeting because you now need to bring in technical assistance helps to develop credibility. This is where 30 years’ experience comes in to its own. You just can’t learn 30 years of experience in a classroom.

A BDM not only has to sell to customers but also must sell those solutions to internal stakeholders too. This can be just as challenging.

Sales targets are not my favourite topic. You build up your pipe line and develop business plans for the following year and the challenge here is to forecast what you will win and in which quarter you will get those purchase orders. Those of you who sell in to the nuclear sector will understand just how difficult this can be!

Control System Advice and Support

If you answer yes to any of the following, then maybe I can be of assistance: –

- Thinking of automating your process but don’t know how to go about it?

- Do you have an old control system which you can’t support and want to replace it but don’t know what’s available on the market?

- Want a new control system but just don’t have the time to look in to the options?

- Not getting good service from your control system provider and don’t understand the jargon they use?

- Want an independent view of the world with no strings attached?

- Just want an honest answer and deal with someone you can trust?

- The control system is a small part of your offering and lack of knowledge is holding your business back from expanding or going for bigger opportunities?

Proposals Support

Supplier point of view – I can develop a technically compliant solution to a client’s user requirements, estimate how much it will cost to deliver that solution, develop a MS programme of how it will be delivered and write it all up in a client focused proposal providing the key selling points and differentiators.

End user point of view – If you need help earlier in the proposal process, then I can work with you to develop your long-term strategy including the development and identification of user requirements. I can also work with you to detail this in a suite of documents that can be used to go out to competitive tender. When those tenders are submitted I can provide independent assistance in the evaluation of those tender returns based on your selection criteria. This could be value for money, technical ability, understanding of the requirements and/or the least risk supplier.

Other reasons why you may want to approach me are:-

- Not having the success you had planned and would like a fresh perspective?

- Have difficulty correctly estimating and keep losing on price?

- Losing on technical assessment and would like to review your proposal structure and key selling points?

- Are you looking for advice on how to ensure you understand and take in to account what your customers want and offer what they are looking for in your tender submission?

- You may be the end user and don’t seem to get the service or the solution you wanted or envisaged? Not sure what to ask for or what is available on the market?

- Or you need additional support because you are just too busy with your other day to day activities and can’t justify recruiting permanent additional staff.

New Build Requirements

When building a new facility there are many aspects to take in to account. The control system and associated electrical and instrumentation systems may be very low down your priority list given the estimated spend for a control system is less than 5% of your budget. However, get the control system requirements wrong and you can add severe delays to your programme while you get the control system built and tested. The control system is the glue that brings everything in your new facility together as one harmonious entity. Engaging with a control system expert will reduce the chances of aspects of your plant or system being missed as they need to understand the plant as a whole to ensure a fully integrated control system solution is realised.

The first aspect of a new facility is developing a design and build budget to analyse the business justification and gain management funding approval. How often are budgets and timescales correctly forecast? Have the right levels of risk/contingency been allocated. Often only the process, mechanical and civils are assessed at this stage. Often little consideration is assigned to the control philosophy or what space will be required for control equipment, motor control centres, power supply systems or control room requirements etc.

Where can I assist?

- Budget Estimates – In the early stages I can work with your designers to develop a high level set of requirements with a broad budget estimate for business justification and sanction. This may also involve an input in to the design, where I can provide guidance on aspects that will reduce the complexity of the control system and not impact on the process or mechanical design budgets. I have had many occasions where the mechanical design has not taken in to consideration how it will be controlled and the resulting control system would have been so complicated, or there was insufficient space allocated, for the electrical, control and instrumentation aspects that it was just not deliverable.

- High Level set of requirements – In order to provide a budget estimate you need to base it on a set of requirements and assumptions otherwise your budget has no basis and is impossible for others to assess, compare or develop further as the design progresses.

I can help you to develop this or review your current requirements and provide an assessment report detailing any recommendations or risk areas. - Client or Contractor – The above is applicable for assisting the client of the new facility or the contractor tendering to build the facility. I can also assist throughout the design, build, test and commissioning phases.

Obsolescence Requirements Capture

There are many questions to ask yourself when looking to replace an aging obsolete control system asset. Things like the following need to be considered: –

- Site Strategy – Do you have a preferred technology used on site? Do you have a software and hardware implementation standard? Do you have a HMI site standard? What technologies are your staff trained in? Do you have a support contract and is it meeting your expectations? Is the technology and its implementation widely available or are you restricted to a single vender? What is your cyber and system resilience strategy?

- Process – Is your process 24/7/365 and when are your planned outages? Is an outage necessary to replace the control system or can it be done piece meal with short outages or transferring redundant systems over one at a time? Have you carried out an assessment to understand what areas of the process need updating to improve efficiency or to meet new regulations? Can we upgrade areas of plant at the same time to improve reliability or repeatability?

- Process Data – Are you making good use of the data available or could you make use of the data if more was provided through the control system? How do you know if you process is meeting your key performance indicators if you are not measuring them. Do you use data to predict maintenance or replace on fail? How easy is it to diagnose plant faults using your current system?

- Operations & Maintenance – Have you carried out workshops with the Operations and Maintenance staff to understand the issues they have and what improvements they think would make a big difference? Are your process descriptions up to date and correct? Do you have too many alarms being presented to the operator? Have you reviewed what training and support you may need moving forward? Have you carried out a Human Factors assessment of your Operations staff.

- Cyber Security – This is an area that will not have been considered previously or perhaps it is because of Cyber that you are looking to replace an aging obsolete control system asset? This is an area that should be considered during the early stages and not as an afterthought retrofit to your system.

- Environment – Is the control room fit for purpose? Does it meet current guidelines? When was a Human Factors assessment last carried out? If you are upgrading the control system will the control room lighting meet the needs of the operators using the new HMI screens. Is the room kept at a constant comfortable temperature? Do you need to control access to your control room for security and/or operator distractions during critical processes such as start-up, shut-down or in an emergency?

Not Found What You’re Looking For?

I may still be able to help. Please feel free to make contact as I’m part of a network of likeminded professionals and may be able to provide the assistance you need through D2MK. If I can’t help, then I may be able to recommend or put you in contact with an organisation that can.